All orders are completed with a short lead-time thanks to our GRS certified factory that has 8,000 square meters of workspace along with our experienced staff. With our robust processing capabilities and close cooperative relationship with upstream chemical factories, we can ensure a steady supply of recycled finished plastic pellets.

Precision and efficiency are the main focus of each of our recycled plastic granule processing, ensuring our capabilities in completing your orders without compromising on quality.

Recycled raw plastic materials are thoroughly washed and sorted upon receiving them. All materials are required to have no impurities such as labels, adhesives, or food residue to guarantee our processed recycled plastic granules are free of any contaminants and have high-purity qualities.

Pieces of recycled plastic go through our shredding equipment to be resized into dry plastic flakes. Turning plastic into dry flakes can reduce the cost and energy it takes to melt them, allowing us to keep the price of our recycled plastic granules at a competitive rate.

Dry plastic flakes are put into the dedicated melting machine and melted down into liquid form of plastic. Furthermore, melted plastic can be processed into recycled plastic granules.

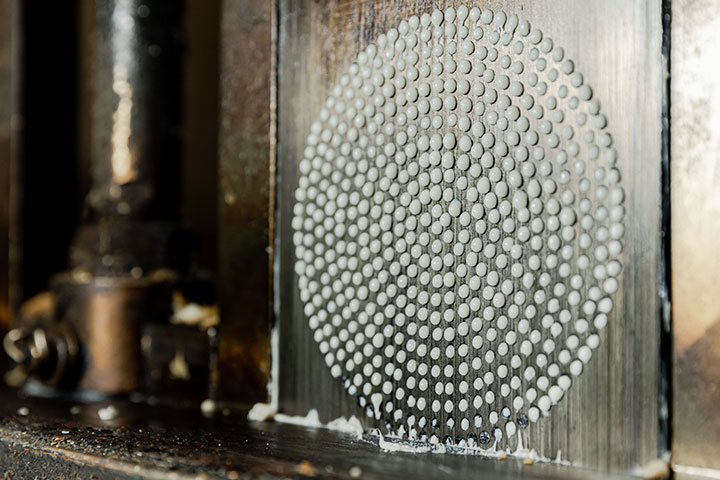

Being compressed into small recycled plastic pellets, Econa’s plastic pellets are ready to be reused or repurposed into new products among different industries such as building material manufacturers, footwear manufacturers, electronic manufacturers, and light fixture producers.

Source high-quality and sustainable recycled plastic pellets from Econa today! Partner with us and set your brand to lasting success.

*We respect your confidentiality and all information are protected.